Custom Die Products to Fit Your Needs

We are a manufacturer of extruder dies, knives, knife holders, drive shafts, and gages. Nixon Tool Co., Inc can customize dies to your specifications easily, and assist you in determining what works for you. We offer onsite training for your extruder operators to ensure proper setup and operation of the dies. Our website has information regarding placing orders, getting technical support, and all of our company and contact information.

Die Bases

Die bases are designed to provide the maximum opening of die face while maintaining enough strength. Materials are taken into careful consideration, and heat treatments and machining processes are also key factors in developing a die base that outperforms your competition. Shown above are blanks that are ready to be made to your exact specifications.

Die Ring Inserts

These inserts are made up of many different materials, including 4140PH, to allow for fast response time and short time runs. D-2 material hardened to RC 60/62 withstands all your long-term, high-abrasion product runs. Titanium coatings are also an option to extend the life of these inserts.

Knife Holders

Adjustable knife holder – We make many different versions of knife holders for various sizes of extruders. Some are adjustable, reducing the number of knife holders needed for operation. By using the “set-up base,” you can preset as many knife holders as you want, have them available for the next die setup, or store them away to have on hand for emergencies. If you happen to break knives during operation, you only have to unscrew one bolt and pull the holder with broken knives off. Then, replace it with a holder with preset knives, and you are ready to go. By loosening four cap screws, adjusting the knife head to the desired position, and tightening the one bolt, you are back in operation with little time lost as this procedure can be completed within 2 minutes.

Non-adjustable knife holder – Our non-adjustable holders are lightweight options for your extruders.

Knives

Knives – We now offer knives made of three different materials: D-2, stainless, and cobalt. We are the only company that makes an L-shaped knife. By having the base of the knife below the cutting path of the die, it prevents the product from being distorted by hitting the cap screws as it is extruded, producing a better-looking product. We also offer a knife resharpener that is simple to use and can reduce the overall cost of your knife usage.

Sharpener – Our knife sharpening system is inexpensive and easy to use. There are two settings on the sharpener: one for the primary cutting edge and the other for the secondary clearance angle of the knife. Some of our customers have resharpened their knives as many as 20 times, which results in a tremendous savings in knife usage.

Driveshafts

We make several different styles of driveshafts. The shaft pictured above is made primarily of John Deere Power Take Off shaft components. This reduces the cost for the customer and makes it possible to repair at the customer’s local John Deere supplier. Shafts are also dismantled just as easily.

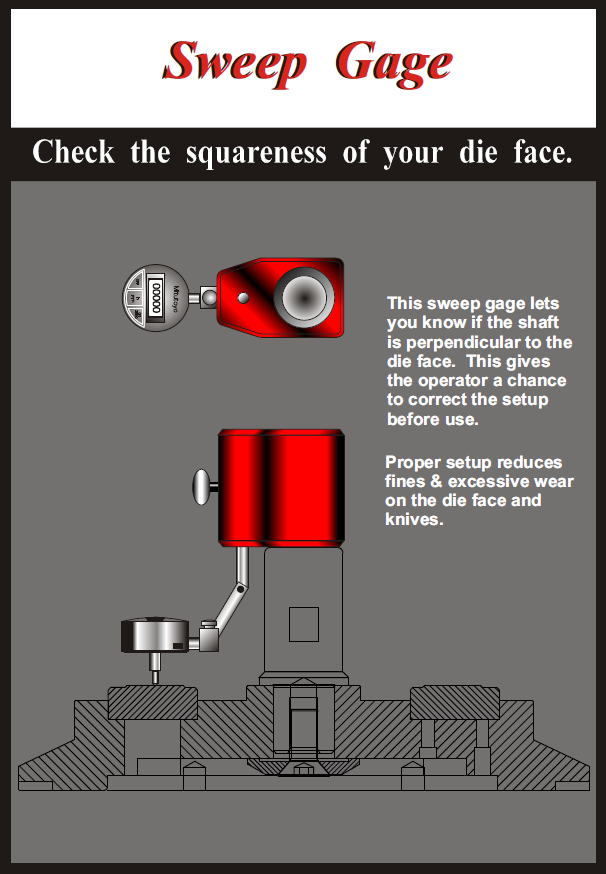

Gages

Knife squareness gage – Checks the squareness of the knife and the width of its base.

Sweep gage – Checks your die face to make sure it is perpendicular to the shaft.

Workstations

Our workstation is made of 2-inch square tubing and is very rigid. We can customize it to meet your specifications. It includes a squareness gage, sweep gage, set-up base, ball end Allen wrenches, a knife sharpening station, V-vise for changing inserts on the die base, storage drawers for preset knife holders, and a stainless steel surface (available upon customer request) on the bench for durability. Our workstation is a convenient and efficient way to set up dies.

Here you can create the content that will be used within the module.